Globe valve is one of the most popular valves, because it’s durable, easy to produce and maintain. Also, it’s suitable for both medium-low pressure and high pressure. It can be used in control of air gas, water, water gas, corrosive medium, slurry, oil, liquid metal and radioactivity medium .etc. | |

Standards | |

Design and Manufacture | BS 1873,ASME B16.34,GB/T12235 |

Face To Face Dimension | ASME B16.10,GB/T 12221 |

Connection Dimension | ASME B16.5,GB/T 9113,JB/T 79,HG/T 20592,ASME B16.25 |

Test and Inspection | API 598,GB/T 13927,GB/T 26480,JB/T 9092 |

Globe Valve Structural Features | |

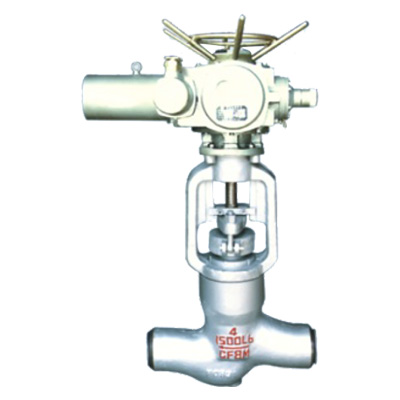

The closure principle of the globe valve is to rely on the pressure of the stem to make the disc sealing surface and the seat sealing surface tight and close to prevent the media from circulating. | |

Globe valve’s face to face length is greater than gate valve’s, and its fluid resistance is high, when under long-time operation, the sealing is not as reliable as gate valve’s. | |

When the globe valve opens, the opening height of the disc reaches 25 % to 30 % of the nominal diameter of the globe valve, and the flow rate has reached its maximum, indicating that the globe valve has reached a fully open position. | |

Back seating design: All our gate valves have the back seating design. In most cases, the carbon steel globe valves is fitted with a renewable back seat. For stainless steel globe valve, the back seat is machined directly in the bonnet or is machined after welding. When the globe valve is at fully open position, the sealing of the back seat can be very reliable. | |

The sealing surface of the seat is spray welded with hard alloy specified by the customer, threaded or welded on seat is also optional for stainless steel gate valve. | |

ill be rolling bearing fitted between stem nut and stem in order to minimize the open and close torque of the globe valve | |

The structure of valve body can be straight-through type, y-globe type and right angle type. | |

Main Material | |

A216-WCB/WCC, A216-LCB/LCC, A351-CF8/CF8M/CF3/CF3M/CF8C, A105, F304/316, etc. | |

Pressure Range | |

CL150~CL2500; PN10~PN320 | |

Size Range | |

1/2”~24”; DN15~DN600 | |

Temperature Range | |

-196℃~+600℃ | |

ASME Globe Valve

ASME Globe Valve ASME Globe Valve 1

ASME Globe Valve 1 ASME Globe Valve 2

ASME Globe Valve 2 ASME Globe Valve 3

ASME Globe Valve 3 ASME Pressure Seal Bonnet Glob

ASME Pressure Seal Bonnet Glob ASME Pressure Seal Bonnet Glob

ASME Pressure Seal Bonnet Glob ASME Electric Globe Valve

ASME Electric Globe Valve ASME Forged Steel Globe Valve

ASME Forged Steel Globe Valve Y-type Slurry Valve

Y-type Slurry Valve| count11 Home Up page Next page End page pages:1/2page 9/page |